Are you searching for “Spray Foam Insulation in Scottsdale“? If so you are probably searching for the best spray foam insulation contractor to help you with your home or business. Barrier Insulation helps residents all over Scottsdale and the rest of the Phoenix metro area. We install the most effective new insulation, remove damaged and old insulation and help keep Arizona residents comfortable and cool. Best of all good insulation means lower energy bills.

Spray foam insulation is the leading 100% water-blown foam insulation that increases energy efficiency by minimizing air leaks. Better insulation also means healthier indoor environments. It blocks pollen, pollution, and other lung and eye irritants from getting into your home.

It also helps block sound from outside and offers greater design freedom. Spray Foam insulation lasts and maintains its performance with no loss of R-value over time. It does not sag, shrink, or settle. Spray Foam adheres to most construction materials and is the perfect insulation for attics, walls, ceilings, and floors. We proudly offer Spray Foam Insulation Valley & State-Wide.

Check out our premier spray foam products Click Here.

Spray Foam Formula

Spray Foam is applied as a liquid and expands to 100 times its volume in mere seconds. This expansion fills every crevice and crack while remaining flexible. This helps maintain the integrity of the building envelope seal remains intact over time. The spray formula has an insulating R-value of 3.6 per inch. It acts as an air barrier and complete insulation solution to seal the building envelope and minimize air leakage for optimal air tightness.

Types Of Spray Foam Insulation

Open Cell Spray Foam – One popular option for Scottsdale homeowners, which is a little less costly upfront, is open cell spray foam. The name “open cell” is descriptive and is indicative of the open bubbles or cells that not closed. During the curing or drying process air becomes trapped between the open or broken bubbles and never completely close. One benefit of this feature is that as heat tries to pass through the air pockets it is slowed by the naturally occurring open areas. Open cell is much softer than closed cell and is water permeable. Depending on the construction application being water permeable is can be beneficial. The R value of the open cell type of spray foam are about a 3.5 R value, or approximately half as effective as the closed cell type.

Closed Cell Spray Foam – The defining feature of closed cell spray foam insulation is that the cells or bubbles in the insulation are much more dense and packed closer together. This increase in density makes for higher thermal performance insulation and a stronger foam than open cell. Closed cell spray foam is air and water tight and will not let either pass through it. The way that it does this is that the bubbles are sealed up, are very close together, and filled with a gas. The insulating performance of closed cell spray foam insulation is an astounding R-7 per inch! Selecting closed cell insulation is the serious solution for the homeowners concerned with saving money on energy bills, increasing the comfort and lifespan of their home.

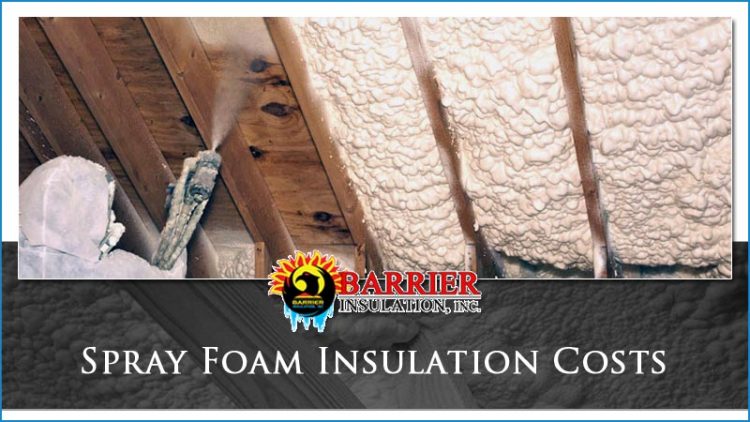

Financial Advantages of Spray Foam Insulation

Home ownership comes with the understanding that the storms will come, the soil will erode, and every home will settle over time. When homes settle they never do so evenly and that leads to cracks, gaps, and holes. These weak points in your home’s exterior will allow air to flow in and out.

This means that your air conditioning and heating is blowing right out of the cracks and the hot or cold air is finding ways into your home. Most of us would agree that we spend enough on utility bills and would enjoy saving money any way we can. The Department of Energy has conducted research that shows that the average American home loses about 30% of its air conditioning through these unavoidable gaps and cracks.

Cracks in home’s structures mean that insulation R values alone aren’t the only thing way to keep your home comfortable and lower energy consumption. If your conditioned air is pouring out all day and night the you need to seal up the gaps with an air tight layer of insulation. This will make your home more efficient and therefore reduce energy costs. Rigid foam board or rolls of fiberglass insulation never fit perfectly into every crevice and space which leaves space for air to get out or in. Spray foam insulation’s feature of expansion is what makes it the best long term cost effective insulation solution.

Reasons Spray Foam Insulation Is Worth It

Homeowners, businesses, and even charity organizations who build houses have realized the value and advantage of spray foam insulation. Spray foam insulation’s advantages include that it seals air leaks, offers better performance, improves indoor air quality, and even helps keep your home quieter.

Seals Air Leaks

One major difference between spray foam insulation and every other type is that spray foam seals gaps and cracks that let air move in or out of your home. This characteristic of spray foam leads to many of it’s unique advantages and superior performance as an insulation option.

Lower Utility Costs

Habitat for humanity did a case study where two identical homes were built. One with traditional fiberglass insulation and one with spray foam insulation. After only 5 months of utility bills the house with spray foam insulation owed $547 dollars less in heating and cooling costs!

Superior Indoor Air Quality

As the air leaks are sealed off allergens and humidity from outdoors is kept outdoors. This helps prevent mold in the home and pollen or dust from entering the home. Many people and children react to both pollen and dust with mild to sever allergic reactions that can significantly impact their quality of life.

A Quieter Home

Another great advantage of spray foam is having a quieter and more peaceful home. Your house is likely the place you come to escape the noise and busied activity of the day. Hearing less of the traffic passing your home and what the neighbors are up to will leave you with a greater sense of relaxation. Spray foam insulation helps keep the noise outside and can even help soundproof rooms inside your home.

Better Resell Value

When you invest in better materials in your home it is worth more money. Spray foam insulation is widely know for its advantages and being able to list that you have the best insulation option helps fetch a better sale value if you decide to move. Best of all once your spray foam insulation is installed you’ll enjoy lower utility bills for the rest of the time you live in the home.

Improved Wall Strength

Spray foam insulation adds strength to the walls of your home as it solidifies. This additional strength will help keep your home standing strong as your it ages and improve the longevity of the structure. So in addition to keeping you more comfortable, lowering utility costs, it will help keep your home in better condition for longer.

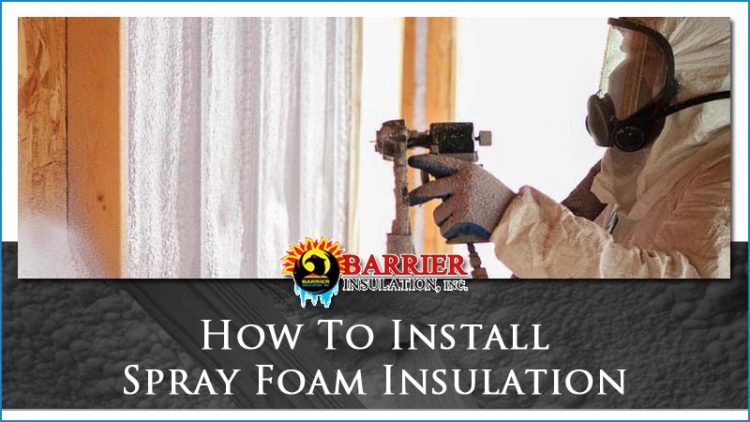

Starting Your Spray Foam Insulation Installation

Starting your spray foam insulation project in the Scottsdale area is as simple as a phone call. We have provided information you need to make decisions for your home insulation project. Barrier Insulation makes insulation installation simple and painless for homeowners all over the state. Take a look at the information here or simply call and we can help you by discussing the options that will work best for your home, your family, and your budget.

Polyurethane foam insulation comes in a number of different configurations, spray foam insulation has the highest R-values and therefore is the most popular type of insulation. It has numerous benefits when compared to more common cellulose and fiberglass insulation. Spray foam is exceptional when upgrading a home or business’ insulation. It is also the go to chose when homeowners are doing major remodels as well as new construction build outs. This foam serves a great air and thermal barrier.

Know Your Needs – Homeowners need to understand the different types of options which are available from new home builders or any insulation contractors. Whether you’re just just want to have lower electricity bills or you are building your dream home should be specific about what type of insulation options are being offered to you and make decisions that get you the best bang for your buck. At Barrier Insulation we inform homeowners and make sure they they know what their options, what they are getting, and providing the best customer service.

Spray foam insulation is applicable to inverted, vertical, or horizontal surfaces in your attic and all areas of your home. With the flexibility of spray foam we will help you decided which areas are best to install the foam and help you make the decision on which type will work best. Spray foam installation is usually applied to the bottom of the roof deck. New construction projects allow us to apply in the material into cavities of the wall or anywhere its needed. After installation we scrape excess foam to make for easier installation of drywall.

If you are planning on using spray foam for your next insulation product, we can help you get the job done. Spray foam simply has the highest R-value of any insulation. This saves you money, energy, and likely increases your property value. Barrier Insulation your Scottsdale spray foam insulation company. Give us a call us today at (602) 499-2922.

Schedule Your Services Today!

Whether you are building a new house, or just need to remove the old insulation and install a newer more energy efficient option Barrier Insulation is Phoenix’s first choice in home and commercial insulation and solar services. We proudly provide the valley’s more comprehensive insulation service that helps you stay more comfortable and save on energy. Click here to schedule on our website, or just give us a call at 602-499-2922.